Engineers work hard to ensure that the equipment is designed for the purpose, is capable of withstanding the stresses, and is productive and cost effective. However, in many cases, the design is a slight modification or progression of existing designs and without a significant focus on the human factor. In my experience engineers often see the human as the weak link in a good design and an element which is difficult to control and can involve unpredictable outcomes. Ergonomics data, about humans and their interactions with tasks, can help take some of the mystery out of the human factor and provide engineers with useful specifications to be incorporated in the equipment design. This presentation discusses the types of contributions ergonomics can make to the design of underground equipment, along with some examples.

Ergonomists and Ergonomics Data

According to the International Ergonomics Association ergonomists contribute to the design and evaluation of tasks, jobs, products, environments and systems in order to make them compatible with the needs, abilities and limitations of people. Ergonomists, in practice, have to address real world problems and seek the best compromise under difficult circumstances while aiming to provide cost effective solutions, according to Stanton et al.

In my experience ergonomists also have other goals, particularly in regard to assisting with design:

- find and apply data on human performance relevantto the design and demands;

- assist the designer/engineer by way of ergonomics specifications;

- assess risk quantitatively, comparing current andintended designs;

- set clear solution goals and specifications whichcan act as a design standard; and

- often provide a neutral or objective opinion utilizing ergonomics data.

Examples of ergonomics data and their application are discussed below.

Anthropometry

Anthropometry is the science which deals with the size and shape of people within a population (Standards Australia Handbook 59-1994). The application of anthropometry, in design, is to incorporate the relevant human dimensions, aiming to accommodate at least 90% of potential users, taking account of both static and dynamic factors. Static factors are such things as height of a lumbar support on a seat backrest, the seat pan depth, the doorway size for access. Dynamic factors relate to movements of the body, reach distances, movement patterns, viewing angles (where a person has to move their head to view from one point to another as part of the process).

Anthropometry is the science which deals with the size and shape of people within a population (Standards Australia Handbook 59-1994). The application of anthropometry, in design, is to incorporate the relevant human dimensions, aiming to accommodate at least 90% of potential users, taking account of both static and dynamic factors. Static factors are such things as height of a lumbar support on a seat backrest, the seat pan depth, the doorway size for access. Dynamic factors relate to movements of the body, reach distances, movement patterns, viewing angles (where a person has to move their head to view from one point to another as part of the process).

A critical example of anthropometry, in this case, is viewing and reaching angles in roof bolting. In this case a miner was suffering chronic neck pain. Analysis of the work revealed typical neck extension in the order of 40-45° as well as maximum reaching to insert the bolt and resin. The height of the floor of the 0continuous miner was found to be such that most people would need to adopt near to 40° neck extension to view the bolt hole as well as significant reach in order to reach forwards and upwards when inserting bolts and resin. The solution involved determining the appropriate floor heights, and forward reach distances to the bolters, in order achieve a suitable degree of neck extension based on typical frequency and duration. The ergonomics data included eye movements v neck movements, the part of the neck involved in the neck extension, human dimensions for eye height and reach capacity, likely forces applied, and other factors. The result was a recommendation to raise the floor of the miner 100-200mm and extend the floor forwards 200mm toward the bolters

Biomechanical Stress Analysis

Biomechanical factors take in all factors related to musculoskeletal stress, including postures, movements, forces, durations and frequencies. There is relevance to all aspects of underground mining even the walking demands placed on Deputies. Ergonomics data is available in relation to muscle strength, joint range of motion, movement patterns, endurance, repetition and speed; for example, a rapid movement can be perhaps 30% weaker than a slow movement.

Biomechanical factors take in all factors related to musculoskeletal stress, including postures, movements, forces, durations and frequencies. There is relevance to all aspects of underground mining even the walking demands placed on Deputies. Ergonomics data is available in relation to muscle strength, joint range of motion, movement patterns, endurance, repetition and speed; for example, a rapid movement can be perhaps 30% weaker than a slow movement.

An example of a particularly non-ergonomics situation, where there appears to be little account taken of biomechanical stresses, is the changing of rollers on gate road conveyors (Photo 3). Here the problems relate

to limited space, unpredictable forces, tight deadlines, awkward postures, poor visibility and inability to use both hands comfortably in the circumstances.

to limited space, unpredictable forces, tight deadlines, awkward postures, poor visibility and inability to use both hands comfortably in the circumstances.

A further example is shuttle car design where there are common problems with seat heights, pedal reach distances, viewing angles and other factors. Shorter workers may be required to half stand up whilst driving or lean outside the confines of the vehicle to see. Even tall workers can have problems with the viewing angles as well as problems fitting their knees between the two opposing seats.

Control Room Ergonomics

In the control room situation there is a mixture of office and visual ergonomics design as well as cognitive and computer-human interaction. The ergonomist has the role of assessing and providing specifications for the layout, the heights, the viewing angles and distances, character heights and contrasts on the screen as well as various other factors. An important issue, shown by research, is the need to support the whole forearm when using the mouse in order to greatly reduce musculoskeletal efforts in the forearm, shoulder and neck.

In the control room situation there is a mixture of office and visual ergonomics design as well as cognitive and computer-human interaction. The ergonomist has the role of assessing and providing specifications for the layout, the heights, the viewing angles and distances, character heights and contrasts on the screen as well as various other factors. An important issue, shown by research, is the need to support the whole forearm when using the mouse in order to greatly reduce musculoskeletal efforts in the forearm, shoulder and neck.

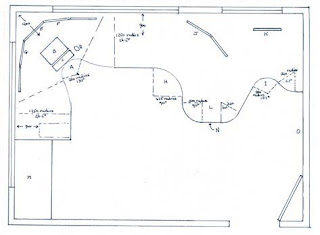

In this example, at a hard rock mining situation, the control room had been designed in a rudimentary fashion resulting quite inappropriate dimensions, poor postures, poor viewing angles and other problems. Solution specifications included the designing of a new three-person console, a new layout for the existing room, a layout allowing easy viewing to the outside to rest the eyes and full forearm support

Source : Ergonomics in the Design Process by Justin O’Sullivan, Ergonomics for Work

0 comments:

Post a Comment